-

Our Products

- Laser Welding Machine

- Laser Marking Machine

- Laser Marker

- Jewelry Laser HallMarking Machine

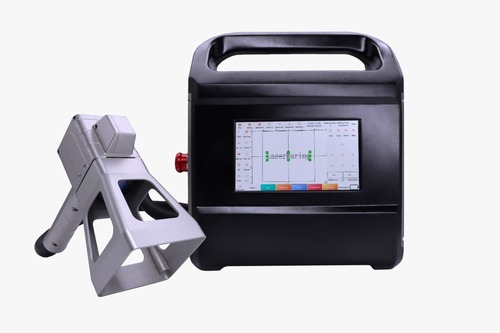

- Portable Laser Marking Machine

- Industrial Laser Marking Machine

- Portable Laser Fiber Marking Machine

- UV Laser Marking Machine

- Co2 Galvo Laser Marking Machine

- Co2 Laser Marking Machine

- Fiber Laser Cutting Machine

- 3D Laser Marking Machine

- Bearing Laser Marking Machine

- Colour Laser Marking Machine

- Desktop Fiber Laser Marking Machine

- Fiber Laser Marking Machine

- Fly Marking Machine

- Galvo Laser Marking Machine

- Handheld Fiber Laser Marking Machine

- Handheld Laser Marking Machine

- Laser Marking Machine

- Metal Laser Marking Machine

- Portable Handheld Laser Marking Machine

- Laser Marking Machine Manufacturer

- Laser Marking Machine Supplier

- Metal Laser Marking Machine

- Fiber Laser Marking Machine

- Laser Engraving Machines

- Laser Marking and Engraving Machine

- Laser Rust Cleaning Machine

- Laser Marking And Engraving Services

- Laser Hallmarking Machine

- SPM Machine

- Laser Optics

- Yag Optics

- Home Page

- Company Profile

- Contact Us

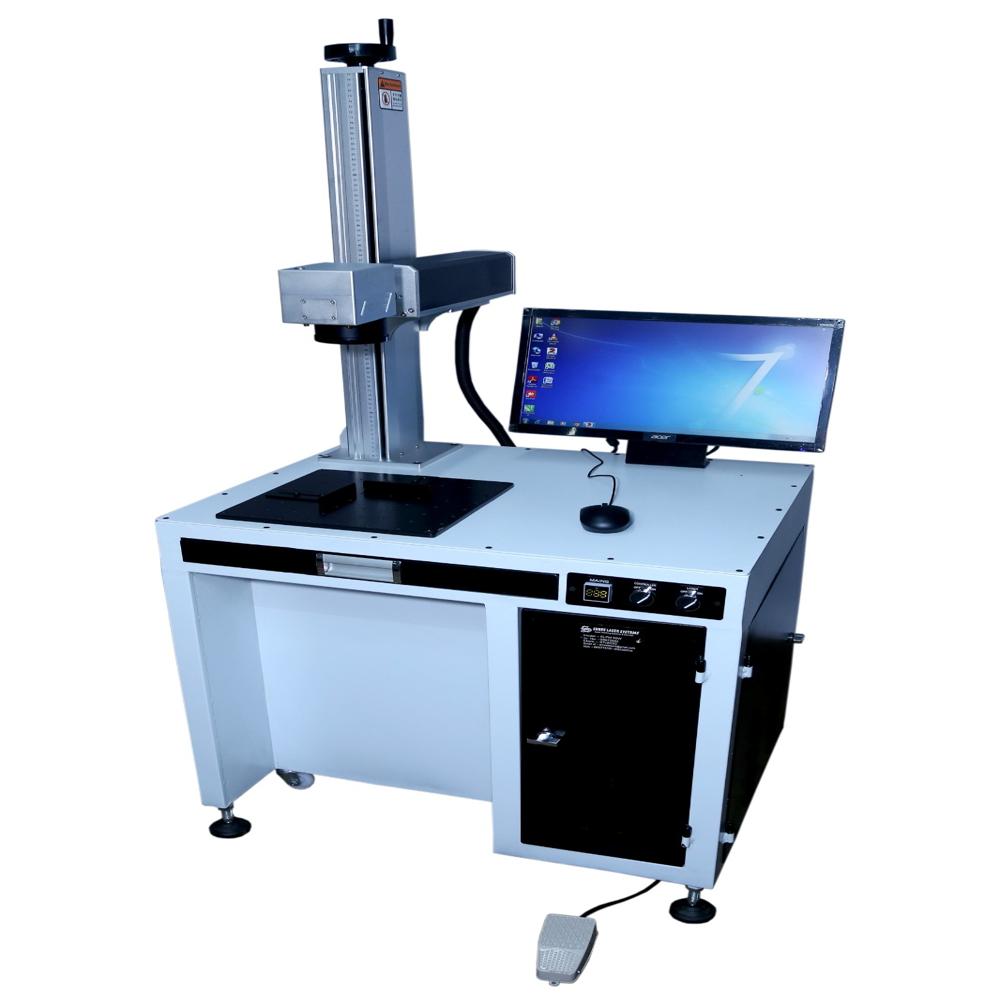

Laser Marking Machine Supplier

145600.0 INR/Piece

Product Details:

X

Laser Marking Machine Supplier Price And Quantity

- 145600.0 INR/Piece

- 1 Piece

Laser Marking Machine Supplier Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 10 Piece Per Month

- 15 Days

- Yes

- Asia, Central America, North America, Africa, Australia, South America, Eastern Europe, Western Europe, Middle East

- All India

Product Description

Shree Laser Systems is a trusted supplier of Laser Welding Machines designed to deliver high-precision, strong, and clean welds for modern industrial applications. These machines use advanced laser beam technology to achieve deep penetration welding with minimal heat input, ensuring excellent weld strength and superior surface finish.

The laser welding process allows accurate joining of metals with low distortion and narrow weld seams, reducing the need for post-weld finishing. The machine is suitable for welding thin to medium-thickness metal components and supports high-speed production with consistent quality.

Laser Welding Machines supplied by Shree Laser Systems are capable of welding stainless steel, mild steel, aluminum, brass, copper, and various alloys, depending on the configuration. The system features an intuitive control interface that enables easy adjustment of welding parameters such as power, speed, and pulse settings.

Widely used across automotive, electronics, jewelry, medical devices, sheet metal fabrication, tools & dies, and engineering industries, this laser welding solution offers energy efficiency, low maintenance, and long service life, making it a cost-effective choice for industrial users.

Frequently Asked Questions (FAQs)

Q1. What is a laser welding machine used for?

A laser welding machine is used for precision welding of metal parts with high strength, minimal distortion, and clean finishing.

Q2. Which materials can be welded using this machine?

The machine can weld stainless steel, mild steel, aluminum, brass, copper, and other metal alloys depending on laser power and setup.

Q3. Is laser welding suitable for thin metal sheets?

Yes, laser welding is ideal for thin sheets and delicate components due to controlled heat input and high accuracy.

Q4. Does the laser welding machine require filler wire?

Laser welding can be performed with or without filler wire based on the application and joint design.

Q5. Is the machine suitable for continuous industrial use?

Yes, the laser welding machines supplied by Shree Laser Systems are designed for continuous industrial operation and high productivity.

Q6. What are the advantages of laser welding over conventional welding?

Laser welding offers faster speed, deeper penetration, minimal heat-affected zones, less distortion, clean weld seams, and reduced rework.

Q7. Is operator training required to use the machine?

Basic operator training is recommended. The machine features a user-friendly interface for easy control of welding parameters.

Q8. What industries commonly use laser welding machines?

Automotive, electronics, jewelry manufacturing, medical equipment, electrical components, metal fabrication, and engineering industries widely use laser welding machines.

Q9. Is after-sales service provided?

Yes, Shree Laser Systems provides installation assistance, operator training, and after-sales service support.

Q10. Why choose Shree Laser Systems as a laser welding machine supplier?

Shree Laser Systems is known for reliable machines, consistent welding quality, industry-grade performance, and dependable customer support.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese