-

Our Products

- Laser Welding Machine

- Laser Marking Machine

- Laser Marker

- Jewelry Laser HallMarking Machine

- Portable Laser Marking Machine

- Industrial Laser Marking Machine

- Portable Laser Fiber Marking Machine

- UV Laser Marking Machine

- Co2 Galvo Laser Marking Machine

- Co2 Laser Marking Machine

- Fiber Laser Cutting Machine

- 3D Laser Marking Machine

- Bearing Laser Marking Machine

- Colour Laser Marking Machine

- Desktop Fiber Laser Marking Machine

- Fiber Laser Marking Machine

- Fly Marking Machine

- Galvo Laser Marking Machine

- Handheld Fiber Laser Marking Machine

- Handheld Laser Marking Machine

- Laser Marking Machine

- Metal Laser Marking Machine

- Portable Handheld Laser Marking Machine

- Laser Marking Machine Manufacturer

- Laser Marking Machine Supplier

- Metal Laser Marking Machine

- Fiber Laser Marking Machine

- Laser Engraving Machines

- Laser Marking and Engraving Machine

- Laser Rust Cleaning Machine

- Laser Marking And Engraving Services

- Laser Hallmarking Machine

- SPM Machine

- Laser Optics

- Yag Optics

- Home Page

- Company Profile

- Contact Us

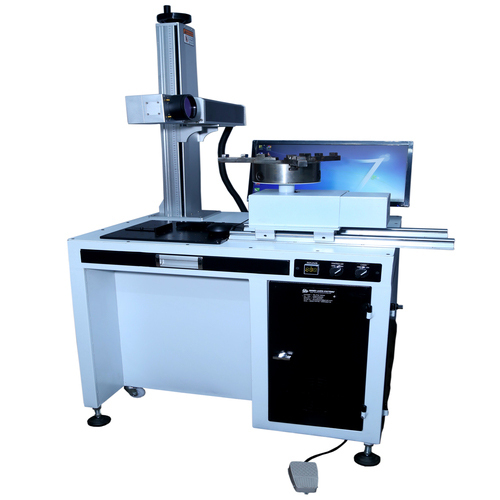

3D Laser Marking Machine

185000.0 INR/Piece

Product Details:

- Condition New

- Usage Industrial

- Laser Type Fiber Laser

- Product Type 3D Laser Marking Machine

- Color Gray

- Click to View more

X

3D Laser Marking Machine Price And Quantity

- 185000.0 INR/Piece

- 1 Piece

3D Laser Marking Machine Product Specifications

- Industrial

- 3D Laser Marking Machine

- Gray

- Fiber Laser

- New

3D Laser Marking Machine Trade Information

- 15 Days

- No

- Maharashtra

Product Description

Shree Laser Systems 3D Laser Marking Machine is an advanced high-precision laser marking solution designed for complex, multi-level, and curved surfaces. Using a 3-axis dynamic focusing system, the machine automatically adjusts focus depth, enabling distortion-free marking on uneven, inclined, curved, stepped, or large-area surfaces.

This technology allows seamless marking on products with varying heights, embossed/engraved surfaces, molds, contours, and deep cavitiesareas where traditional 2D laser systems cannot reach. Equipped with a powerful fiber/UV/CO laser source (as required), it ensures stable performance, ultra-fine detailing, and long service life.

Ideal for industries needing premium, accurate, and flexible marking quality, the 3D laser marking system is widely used for electronics, automotive parts, molds, tools, jewelry, branding, and packaging applications.

Key Features

-

3-Axis Dynamic Focusing System for marking irregular, curved, and multi-level surfaces

-

Large & Adjustable Marking Area (up to 300300 mm or more)

-

High-Speed Galvo Technology for fast and precise marking

-

Perfect for Deep Cavities & Height Variation Surfaces

-

Superior Marking Accuracy for micro-text, serial numbers, logos, QR codes

-

Compatible with Multiple Materials metals, plastics, ceramics, coatings, etc.

-

High Beam Quality Fiber Laser Source with long life (up to 100,000 hours)

-

User-Friendly 3D Marking Software with STL/OBJ/DXF compatibility

-

Energy Efficient & Low Maintenance

-

Supports Deep Engraving and High-Quality 3D Relief Engraving

Applications

-

Curved and cylindrical components

-

Auto parts & engine components

-

Molds and die surfaces

-

Smartphones, electronic housings, connectors

-

Jewelry, tools & branding

-

Embossed/engraved surfaces

-

Packaging, plastics & decorative items

-

Industrial parts requiring multi-height marking

Frequently Asked Questions (FAQs)

1. What is a 3D Laser Marking Machine?

It is a laser system that uses a 3-axis dynamic focus to mark on uneven, curved, multi-layer, and large-area surfaces with high accuracy.

2. What materials can it mark?

Metals (SS, MS, brass, aluminum, copper), plastics, ceramic, coated materials, ABS, anodized surfaces, etc.

3. What is the difference between 2D and 3D marking?

2D machines mark only flat surfaces.

3D machines adjust the laser focus in real-time to mark curved, inclined, multi-height, and complex shapes.

4. What is the typical marking area?

Common areas:

-

150150 mm

-

200200 mm

-

300300 mm

(Customizable)

5. What wattage options are available?

Usually available in 20W, 30W, 50W, 60W, 100W depending on marking depth and speed.

6. Can it mark large or deep cavities?

Yes. The dynamic Z-axis allows deep cavity marking and compensation for height variations.

7. Does it support QR codes and barcodes?

Yes, it marks QR codes, barcodes, serial numbers, text, logos, graphics, and micro-marking.

8. Is the system air-cooled?

Most fiber models are air-cooled. UV or CO types may require minimal cooling.

9. What is the laser life?

Fiber laser sources have a lifespan of up to 100,000 working hours.

10. Is this suitable for high-volume production?

Yes, it is designed for continuous industrial operation with stable and repeatable results.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese